-

- Automatic Rigid Box Making Machine

PRODUCT DETAIL

Horizontal And Vertical Automatic Steering Slotting Machine

LS-1200C is a grooving machine for perating simply with blade seats are consists of high accuracy sliding block and rotation gear wheel. The narrow and wide belts ensure setting any grooving position. Suiteable for more products. The paper feeding aligning system.Availability: Quantity: -

LS-1200C

-

longxingsheng

LS-1200C introduction

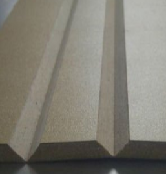

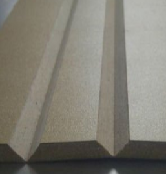

1200C is a slotting machine that can automatically switch between horizontal and vertical slotting. The machine can adjust the angle, high-speed automatic feeding, automatic deviation correction, and automatic receiving. This machine can using in cardboard and MDF board.

Machine parameters

Machine model

LS-1200C

Grooving blade quantity

4

Working speed

35m/min(100-200pcs/min)

Cardboard size

140*120-600*600mm

Cardboard thickness

0.5-4mm

Carton paper thickness

500-800g/m2

Blade material

Tungsten steel

Grooving speed

100-130PCS

Grooving Blade type

V grooving

Min grooving gap (between two grooves)

0 (2 lines blade design)

Motor power

4.5 kw/380v 3 phase

Machine dimension

L2050*W1320*H1350mm

Machine weight

3520kg

Precision is a critical aspect of any grooving operation, and this machine excels at it. Equipped with advanced sensors and cutting-edge technology to ensure precise grooves with minimal deviation. Not only does this improve the overall quality of the finished product, it also reduces material waste, resulting in cost savings for the manufacturer.

In terms of safety, the machine is equipped with various safety functions to protect operators and prevent accidents. Emergency stop buttons, protective covers, and automatic shut-off mechanisms are just a few examples of the safety measures incorporated into their design. This ensures a safe working environment and peace of mind for operators and business owners.

LS-1200C introduction

1200C is a slotting machine that can automatically switch between horizontal and vertical slotting. The machine can adjust the angle, high-speed automatic feeding, automatic deviation correction, and automatic receiving. This machine can using in cardboard and MDF board.

Machine parameters

Machine model

LS-1200C

Grooving blade quantity

4

Working speed

35m/min(100-200pcs/min)

Cardboard size

140*120-600*600mm

Cardboard thickness

0.5-4mm

Carton paper thickness

500-800g/m2

Blade material

Tungsten steel

Grooving speed

100-130PCS

Grooving Blade type

V grooving

Min grooving gap (between two grooves)

0 (2 lines blade design)

Motor power

4.5 kw/380v 3 phase

Machine dimension

L2050*W1320*H1350mm

Machine weight

3520kg

Precision is a critical aspect of any grooving operation, and this machine excels at it. Equipped with advanced sensors and cutting-edge technology to ensure precise grooves with minimal deviation. Not only does this improve the overall quality of the finished product, it also reduces material waste, resulting in cost savings for the manufacturer.

In terms of safety, the machine is equipped with various safety functions to protect operators and prevent accidents. Emergency stop buttons, protective covers, and automatic shut-off mechanisms are just a few examples of the safety measures incorporated into their design. This ensures a safe working environment and peace of mind for operators and business owners.

Related Products

Quick Links

Contact Us