| Availability: | |

|---|---|

| Quantity: | |

LS-450PLUS

Longxingsheng

LS-450plus is a multi-function visual positioning machine. It is able to positioning the rigid box and hardcover. also can do paper lining, one machine with many functions, and the working model is able to be changed by one button. The visual positioning system is able to be upgraded. Moreover, this machine also can be upgraded to an automatic line in the future if needed.

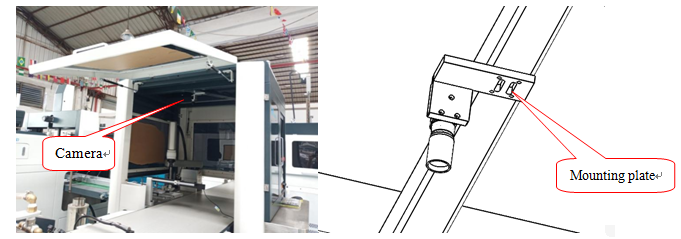

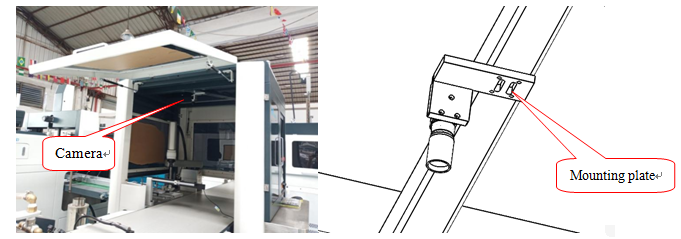

Equipped with dual cameras, the cameras are located on both sides of the central position of the conveyor belt. The camera position has been calibrated before leaving the factory. If there is any deviation, you can adjust the camera position by adjusting the upper camera "mounting plate". After the camera takes a picture, the system recognizes the color difference of the photo for positioning. If the surface paper and the surface paper conveyor belt are similar in color, it can be solved by changing the belt color.

The machine has two conveying systems, which are widely applicable. One conveys boxes, and the other conveys album covers and book covers (hardcover/book covers). The machine has a key to switch modes. It can be used to make boxes or leather cases (hardcover/book cover), and to change the working mode, it only needs to switch with one button, which is easy to operate and saves working time. The machine not only guarantees the customer in terms of operating efficiency, but also solves the customer's concerns about how the machine operates.

The machine is multifunctional, not only used by manufacturers who produce boxes, but also for factories that produce book covers, it is the best choice for customers

6. Panasonic Servo motor feeding system..

Flexible

High speed

Save setting time

Glue Viscosity Device : Automatic detecting the hot melt glue thickness.

Air Operated Double Diaphragm Pump: Applied in white glue pumping.

Bottom sucker hardcover feeding device: Special design for feeding hardcover, to avoid scraping hardcover.

| Type | LS-450plus |

| Paper size (Max) | L800*W600mm |

| Paper size (Min) | L135*W100mm |

| Max box size | L600*W400*H120mm |

| Min box size | L80*W65*H15mm |

| Book cover (Max) | L750*W450mm |

| Book cover (Min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 280mm |

| Motor power / voltage | 7.5kw/380v, 3 phase |

| Heating power | 8kw/380v, 3 phase |

| Air supply | 10L/min 0.6Mpa |

| Working speed | 15-45 sheets/min |

| Machine dimension | L5980*W3180*H2100mm |

| Weight of machine | 2100kg |

Automatic production line suitable for all kinds of rigid box

Fault diagnosis function

Automatically sucking the cover paper and feeding the cardboard

High-precision cam feeding system

Panasonic servo control system

Visual positioning system and machine grasping

Using Yamaha Robot

Adopt a new cycle temperature control gluing system

Using high-definition camera positioning

Can accurately locate the rigid box, cardboard, hardcover

The machine is multifunctional, not only used by manufacturers who produce boxes, but also for factories that produce book covers, it is the best choice for customers

LS-450plus is a multi-function visual positioning machine. It is able to positioning the rigid box and hardcover. also can do paper lining, one machine with many functions, and the working model is able to be changed by one button. The visual positioning system is able to be upgraded. Moreover, this machine also can be upgraded to an automatic line in the future if needed.

Equipped with dual cameras, the cameras are located on both sides of the central position of the conveyor belt. The camera position has been calibrated before leaving the factory. If there is any deviation, you can adjust the camera position by adjusting the upper camera "mounting plate". After the camera takes a picture, the system recognizes the color difference of the photo for positioning. If the surface paper and the surface paper conveyor belt are similar in color, it can be solved by changing the belt color.

The machine has two conveying systems, which are widely applicable. One conveys boxes, and the other conveys album covers and book covers (hardcover/book covers). The machine has a key to switch modes. It can be used to make boxes or leather cases (hardcover/book cover), and to change the working mode, it only needs to switch with one button, which is easy to operate and saves working time. The machine not only guarantees the customer in terms of operating efficiency, but also solves the customer's concerns about how the machine operates.

The machine is multifunctional, not only used by manufacturers who produce boxes, but also for factories that produce book covers, it is the best choice for customers

6. Panasonic Servo motor feeding system..

Flexible

High speed

Save setting time

Glue Viscosity Device : Automatic detecting the hot melt glue thickness.

Air Operated Double Diaphragm Pump: Applied in white glue pumping.

Bottom sucker hardcover feeding device: Special design for feeding hardcover, to avoid scraping hardcover.

| Type | LS-450plus |

| Paper size (Max) | L800*W600mm |

| Paper size (Min) | L135*W100mm |

| Max box size | L600*W400*H120mm |

| Min box size | L80*W65*H15mm |

| Book cover (Max) | L750*W450mm |

| Book cover (Min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 280mm |

| Motor power / voltage | 7.5kw/380v, 3 phase |

| Heating power | 8kw/380v, 3 phase |

| Air supply | 10L/min 0.6Mpa |

| Working speed | 15-45 sheets/min |

| Machine dimension | L5980*W3180*H2100mm |

| Weight of machine | 2100kg |

Automatic production line suitable for all kinds of rigid box

Fault diagnosis function

Automatically sucking the cover paper and feeding the cardboard

High-precision cam feeding system

Panasonic servo control system

Visual positioning system and machine grasping

Using Yamaha Robot

Adopt a new cycle temperature control gluing system

Using high-definition camera positioning

Can accurately locate the rigid box, cardboard, hardcover

The machine is multifunctional, not only used by manufacturers who produce boxes, but also for factories that produce book covers, it is the best choice for customers