| Availability: | |

|---|---|

| Quantity: | |

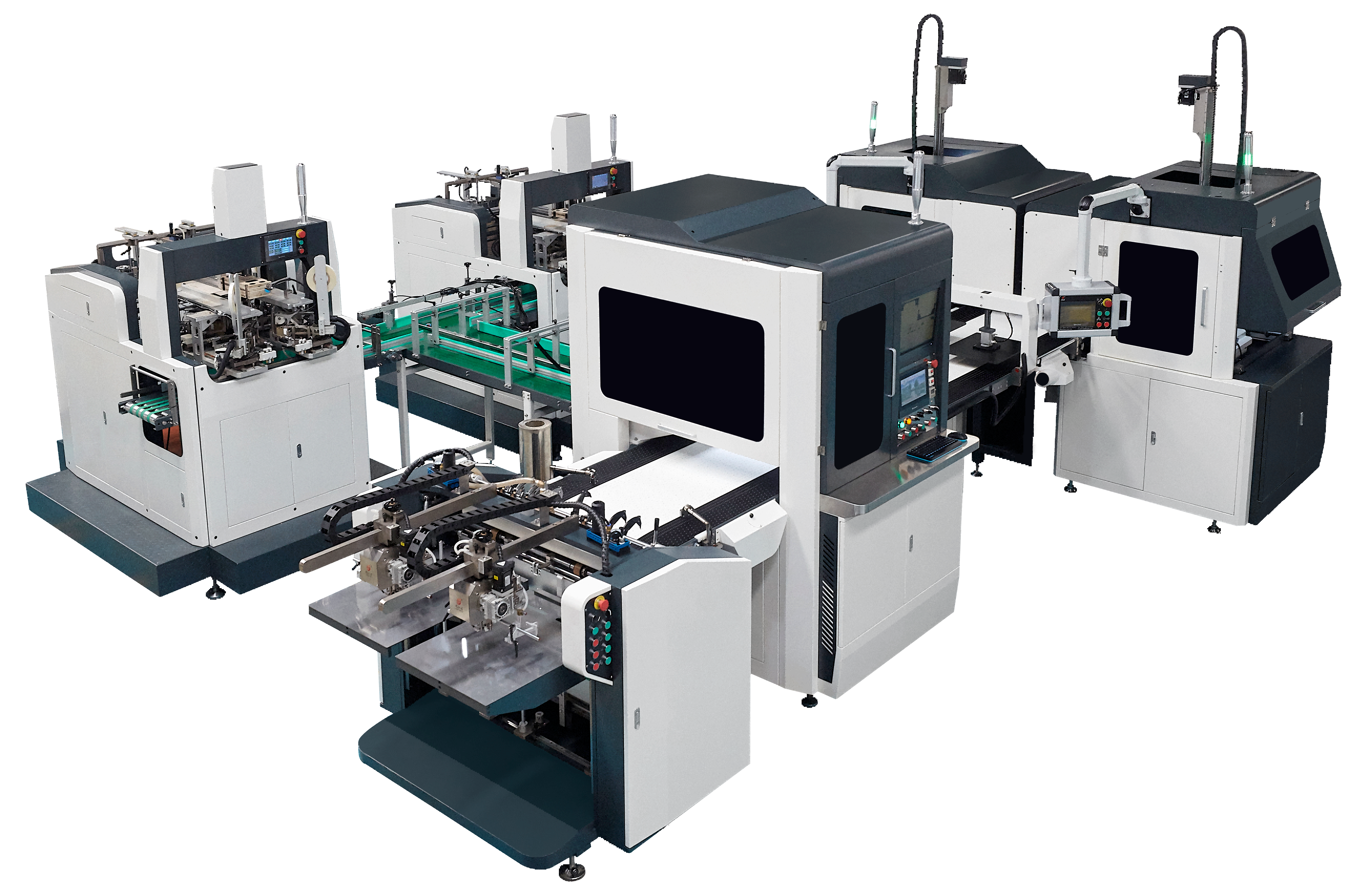

LS-900A

Longxingsheng

Utilizing Mitsubishi servo motors and PLC servo motors, this machine guarantees outstanding performance and reliability. To further enhance production efficiency and stability, it is equipped with a high-precision YAMAHA robotic arm. With a production capacity ranging from 12 to 25 pairs of boxes per minute, this machine is well-equipped to handle large-scale orders. Moreover, its adjustable speed feature allows for seamless adaptation to smaller order quantities, ensuring flexibility in production.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

Efficient production: The fully automatic dual-purpose hard box making machine utilizes advanced technology and automated processes to efficiently produce high-quality hard boxes in a short time. This allows gift manufacturers to meet customer demands and increase production capacity.

Precision Manufacturing: The machine has a precise control system that ensures the size, shape and assembly of each hard box are consistent. This precise manufacturing ensures the appearance quality and packaging effect of the gifts, and enhances the brand image.

Multifunctional design: The fully automatic dual-purpose hard box making machine has multiple functions and can adapt to different types of hard box manufacturing needs. It can manufacture hard boxes of various shapes and sizes, providing gift manufacturers with greater flexibility and creativity.

Save labor costs: Due to the fully automated manufacturing process, this machine can reduce dependence on labor, thereby reducing labor costs. This helps gift manufacturers increase their profits and offer more competitive prices.

Quality Assurance: The fully automatic dual-purpose hard box making machine uses high-quality materials and advanced manufacturing technology to ensure that the manufactured hard boxes are highly stable and durable. This helps ensure that the gift is not damaged during shipping and use.

The advantages of employing automatic machines are numerous—enhanced efficiency, consistent quality, reduced production time, and greater flexibility in meeting diverse market demands.

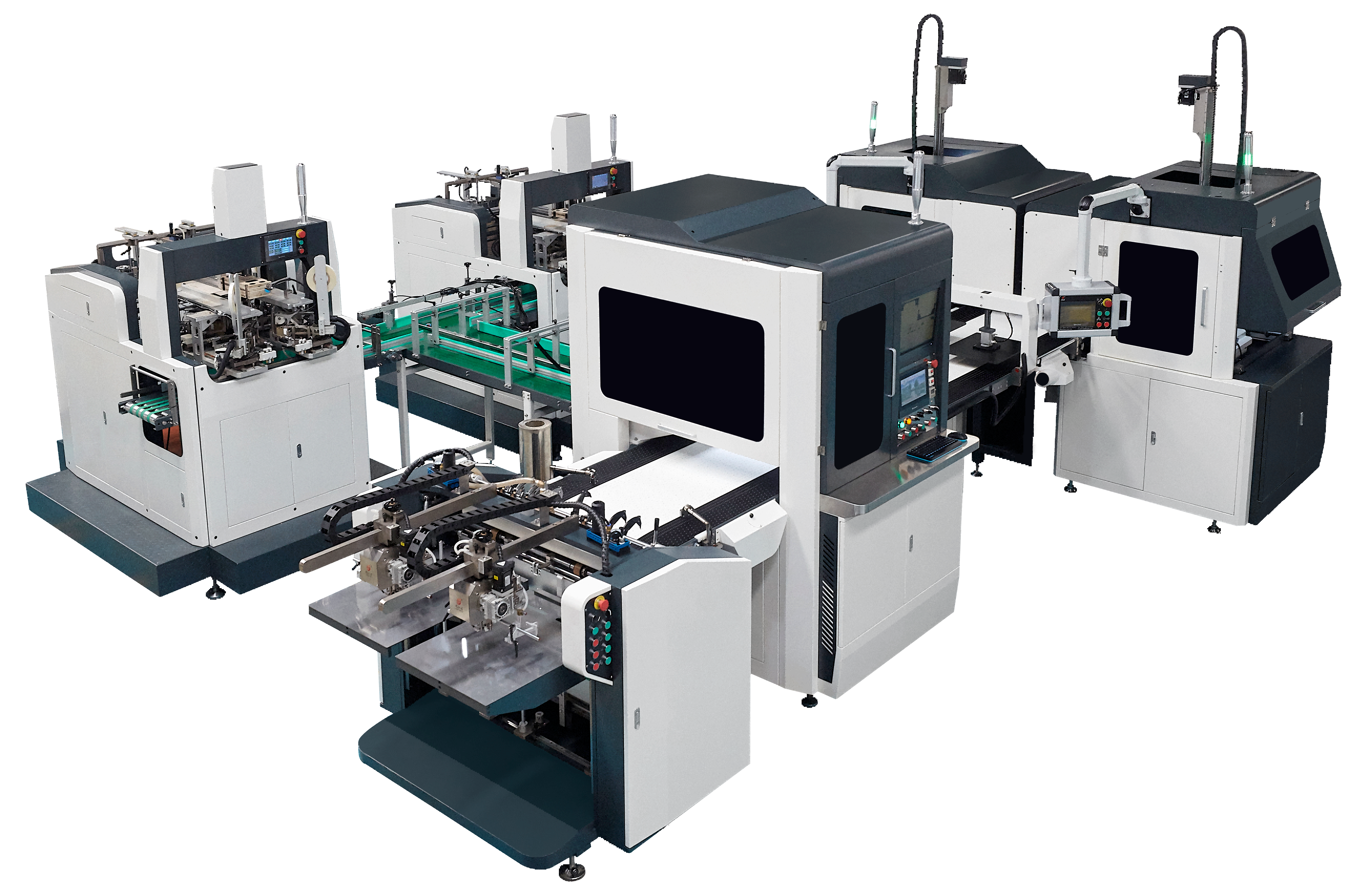

Utilizing Mitsubishi servo motors and PLC servo motors, this machine guarantees outstanding performance and reliability. To further enhance production efficiency and stability, it is equipped with a high-precision YAMAHA robotic arm. With a production capacity ranging from 12 to 25 pairs of boxes per minute, this machine is well-equipped to handle large-scale orders. Moreover, its adjustable speed feature allows for seamless adaptation to smaller order quantities, ensuring flexibility in production.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

Efficient production: The fully automatic dual-purpose hard box making machine utilizes advanced technology and automated processes to efficiently produce high-quality hard boxes in a short time. This allows gift manufacturers to meet customer demands and increase production capacity.

Precision Manufacturing: The machine has a precise control system that ensures the size, shape and assembly of each hard box are consistent. This precise manufacturing ensures the appearance quality and packaging effect of the gifts, and enhances the brand image.

Multifunctional design: The fully automatic dual-purpose hard box making machine has multiple functions and can adapt to different types of hard box manufacturing needs. It can manufacture hard boxes of various shapes and sizes, providing gift manufacturers with greater flexibility and creativity.

Save labor costs: Due to the fully automated manufacturing process, this machine can reduce dependence on labor, thereby reducing labor costs. This helps gift manufacturers increase their profits and offer more competitive prices.

Quality Assurance: The fully automatic dual-purpose hard box making machine uses high-quality materials and advanced manufacturing technology to ensure that the manufactured hard boxes are highly stable and durable. This helps ensure that the gift is not damaged during shipping and use.

The advantages of employing automatic machines are numerous—enhanced efficiency, consistent quality, reduced production time, and greater flexibility in meeting diverse market demands.