| Availability: | |

|---|---|

| Quantity: | |

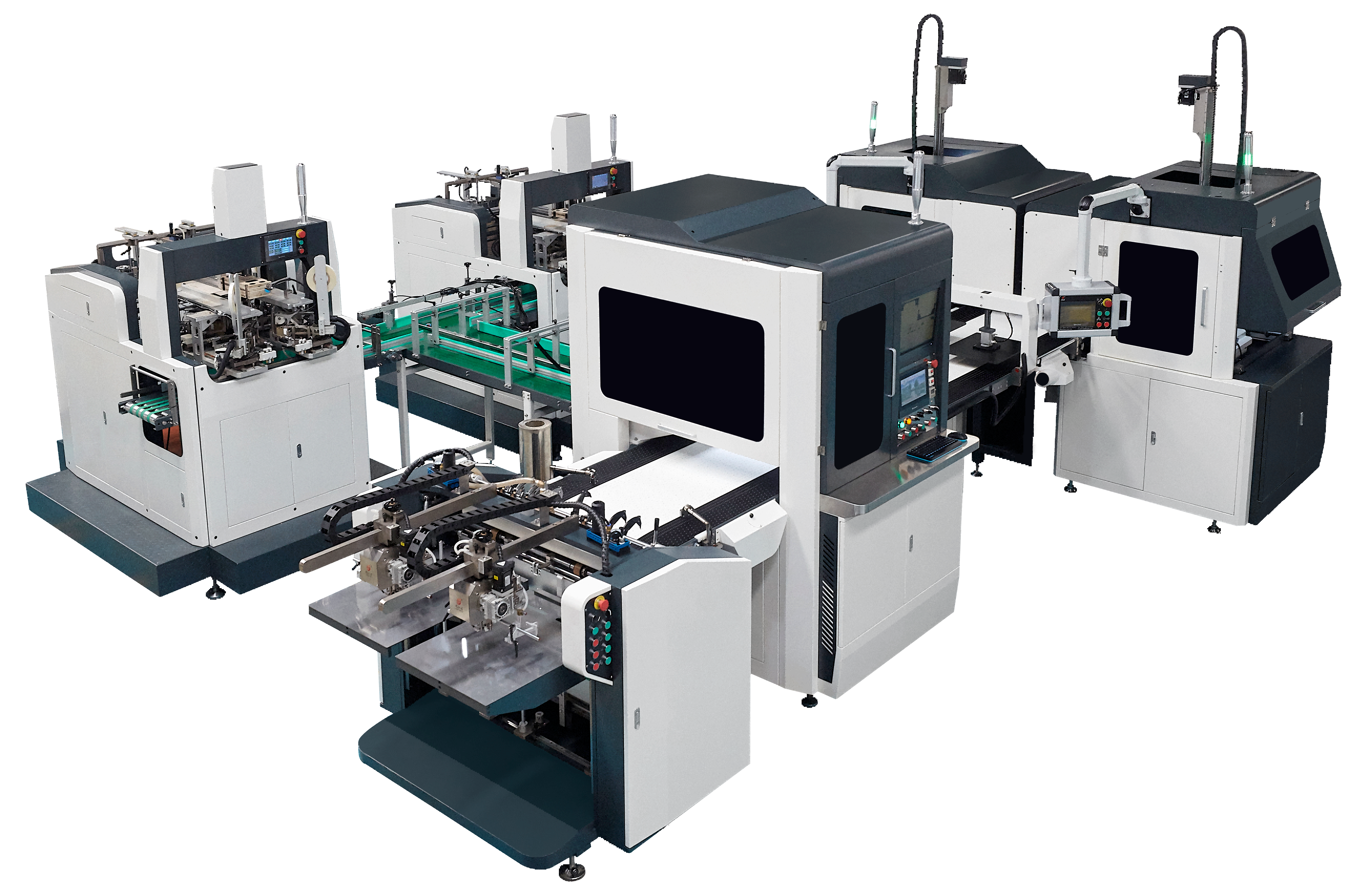

LS-900A

Longxingsheng

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

1."Efficiency and Precision Combined: Our Rigid Box Maker creates flawless, high-quality boxes with speed and accuracy, ensuring your packaging needs are met with excellence."

2."Streamline Your Packaging Process: Our Box Making Machine revolutionizes the way you produce rigid boxes, optimizing productivity and minimizing manual labor. Experience seamless box assembly like never before."

3."Unleash Your Brand's Potential: Our Rigid Packaging Machine empowers you to showcase your products in stunning, professionally crafted boxes. Elevate your brand image and leave a lasting impression on your customers."

4."Seamless Box Formation: Our Box Forming Equipment delivers seamless and consistent box folding, ensuring every corner is perfectly aligned. Trust in our machine's precision for impeccable box assembly."

5."Effortless Rigid Box Manufacturing: With our Rigid Box Maker, producing stylish and durable boxes has never been easier. Maximize efficiency and minimize production time, giving your business a competitive edge."

Experience the convenience and efficiency of the Fully Automatic Intelligent Rigid Box Making Machine. Its professional tone and robust features make it the ideal choice for businesses in need of high-quality box production.

Dual Station Function: Our Dual Station Function machines combine two basic functions in one system. It effectively positions and aligns hard covers for hard box production. By integrating these capabilities, we streamline the manufacturing process, saving time and effort while ensuring productivity.

Precise Box Positioning: Our machine ensures precise positioning of hard covers, resulting in perfectly aligned rigid boxes. It employs advanced sensors and precision mechanisms to guarantee accurate placement, maintaining the integrity of the box structure. This precision enhances the overall aesthetics and functionality of the rigid boxes.

User-Friendly Interface: The machine features a user-friendly interface that simplifies operation and customization. You can easily adjust settings such as cover size, positioning angles, and alignment accuracy to meet your specific requirements. This flexibility allows for versatile production, accommodating different box dimensions and cover styles.

Flexible adaptability: Our machines can adapt to various box specifications and sizes, from standard boxes to boxes with special shapes and sizes. You can adjust and customize it to your specific needs to produce the ideal packaging for your product.

5.Automated operation: The rigid box fully automatic box making machine adopts advanced automation technology and can realize the entire process of automated operation from raw material feeding, folding, gluing to final packaging. This not only improves production efficiency, but also reduces the possibility of manual intervention and operational errors.

6.High-quality box-making results: Our machines are equipped with precise positioning technology to ensure that each box has consistent dimensions and a perfect appearance. Whether it is appearance design or structural stability, our machines can provide high-quality box making results, adding a professional and refined image to your products.

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

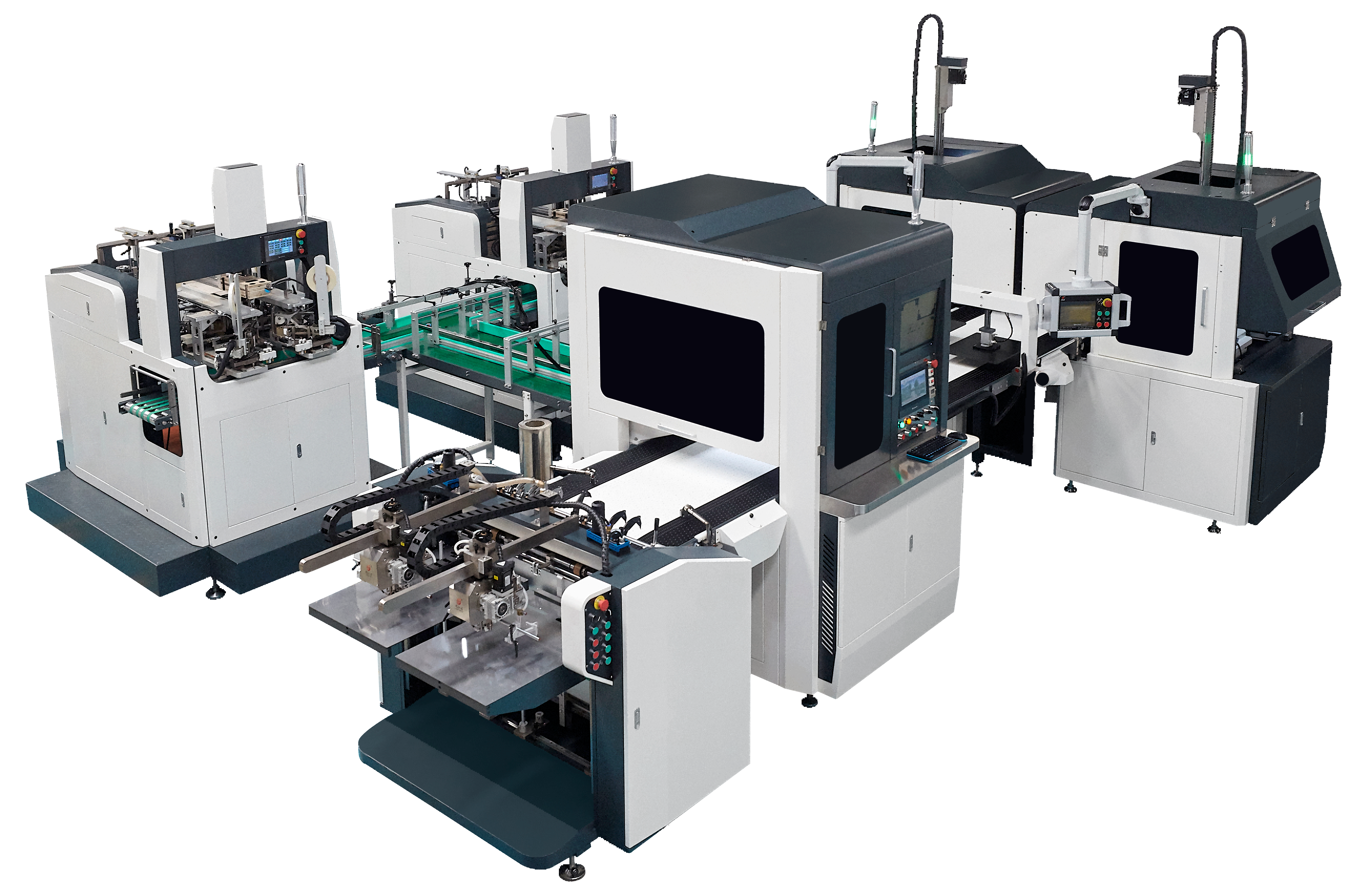

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

1."Efficiency and Precision Combined: Our Rigid Box Maker creates flawless, high-quality boxes with speed and accuracy, ensuring your packaging needs are met with excellence."

2."Streamline Your Packaging Process: Our Box Making Machine revolutionizes the way you produce rigid boxes, optimizing productivity and minimizing manual labor. Experience seamless box assembly like never before."

3."Unleash Your Brand's Potential: Our Rigid Packaging Machine empowers you to showcase your products in stunning, professionally crafted boxes. Elevate your brand image and leave a lasting impression on your customers."

4."Seamless Box Formation: Our Box Forming Equipment delivers seamless and consistent box folding, ensuring every corner is perfectly aligned. Trust in our machine's precision for impeccable box assembly."

5."Effortless Rigid Box Manufacturing: With our Rigid Box Maker, producing stylish and durable boxes has never been easier. Maximize efficiency and minimize production time, giving your business a competitive edge."

Experience the convenience and efficiency of the Fully Automatic Intelligent Rigid Box Making Machine. Its professional tone and robust features make it the ideal choice for businesses in need of high-quality box production.

Dual Station Function: Our Dual Station Function machines combine two basic functions in one system. It effectively positions and aligns hard covers for hard box production. By integrating these capabilities, we streamline the manufacturing process, saving time and effort while ensuring productivity.

Precise Box Positioning: Our machine ensures precise positioning of hard covers, resulting in perfectly aligned rigid boxes. It employs advanced sensors and precision mechanisms to guarantee accurate placement, maintaining the integrity of the box structure. This precision enhances the overall aesthetics and functionality of the rigid boxes.

User-Friendly Interface: The machine features a user-friendly interface that simplifies operation and customization. You can easily adjust settings such as cover size, positioning angles, and alignment accuracy to meet your specific requirements. This flexibility allows for versatile production, accommodating different box dimensions and cover styles.

Flexible adaptability: Our machines can adapt to various box specifications and sizes, from standard boxes to boxes with special shapes and sizes. You can adjust and customize it to your specific needs to produce the ideal packaging for your product.

5.Automated operation: The rigid box fully automatic box making machine adopts advanced automation technology and can realize the entire process of automated operation from raw material feeding, folding, gluing to final packaging. This not only improves production efficiency, but also reduces the possibility of manual intervention and operational errors.

6.High-quality box-making results: Our machines are equipped with precise positioning technology to ensure that each box has consistent dimensions and a perfect appearance. Whether it is appearance design or structural stability, our machines can provide high-quality box making results, adding a professional and refined image to your products.

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.