| Availability: | |

|---|---|

| Quantity: | |

LS-450XL

Longxingsheng

This is a semi-automatic vision positioning machine. The maximum size of leather/book case that can be made is 750*450mm, and the minimum size is 150*100mm. 15-40 boxes can be made per minute. It can make book case, notebook case, novel leather case, case liner, paper lamination, etc. The machine runs fast. The suitcase conveyor belt can transport five suitcases at a time, which is the largest in the market. The conveyor belt has a suction function to prevent the suitcase paper from being scratched and effectively reduce the waste of customer materials.

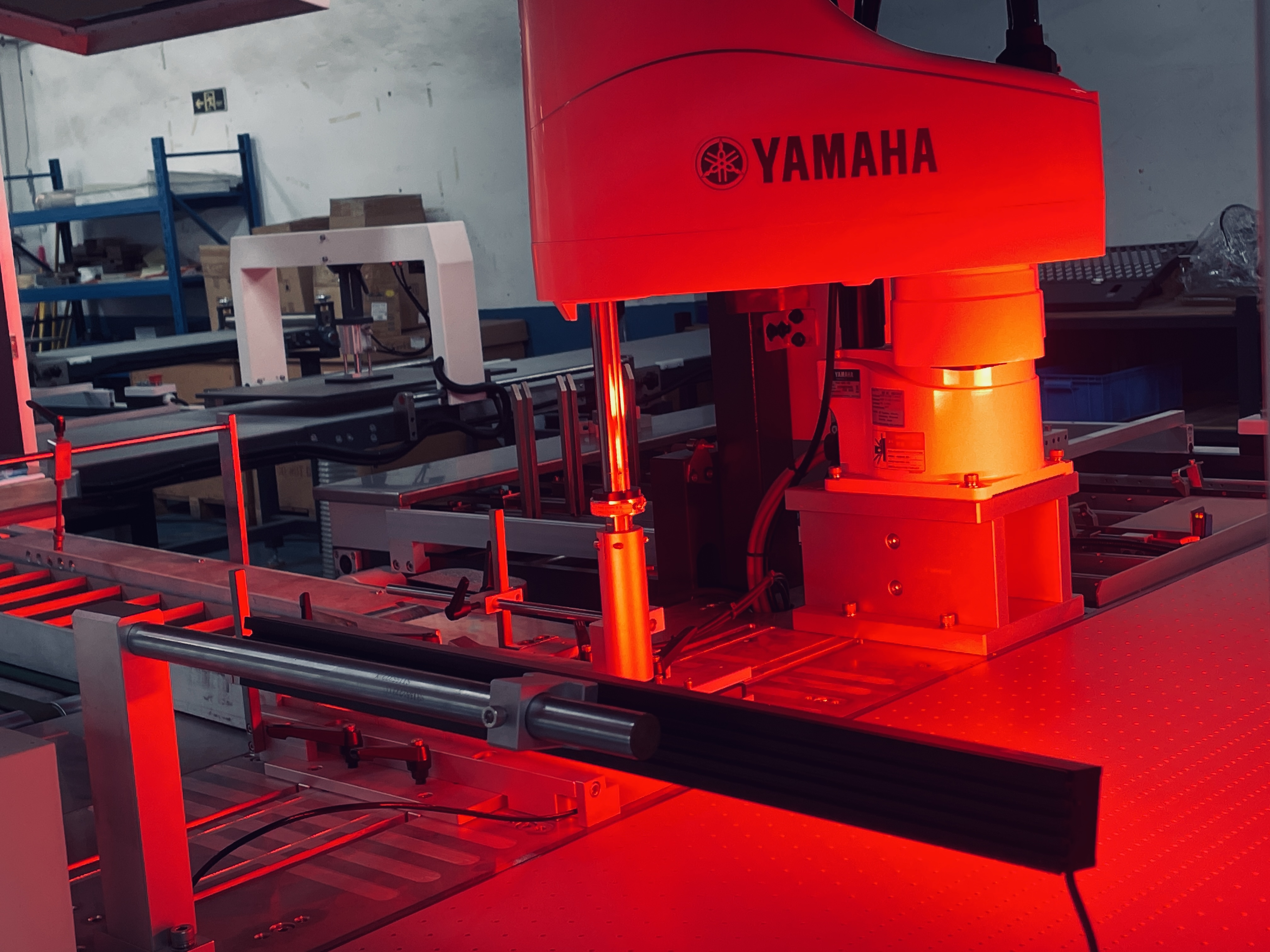

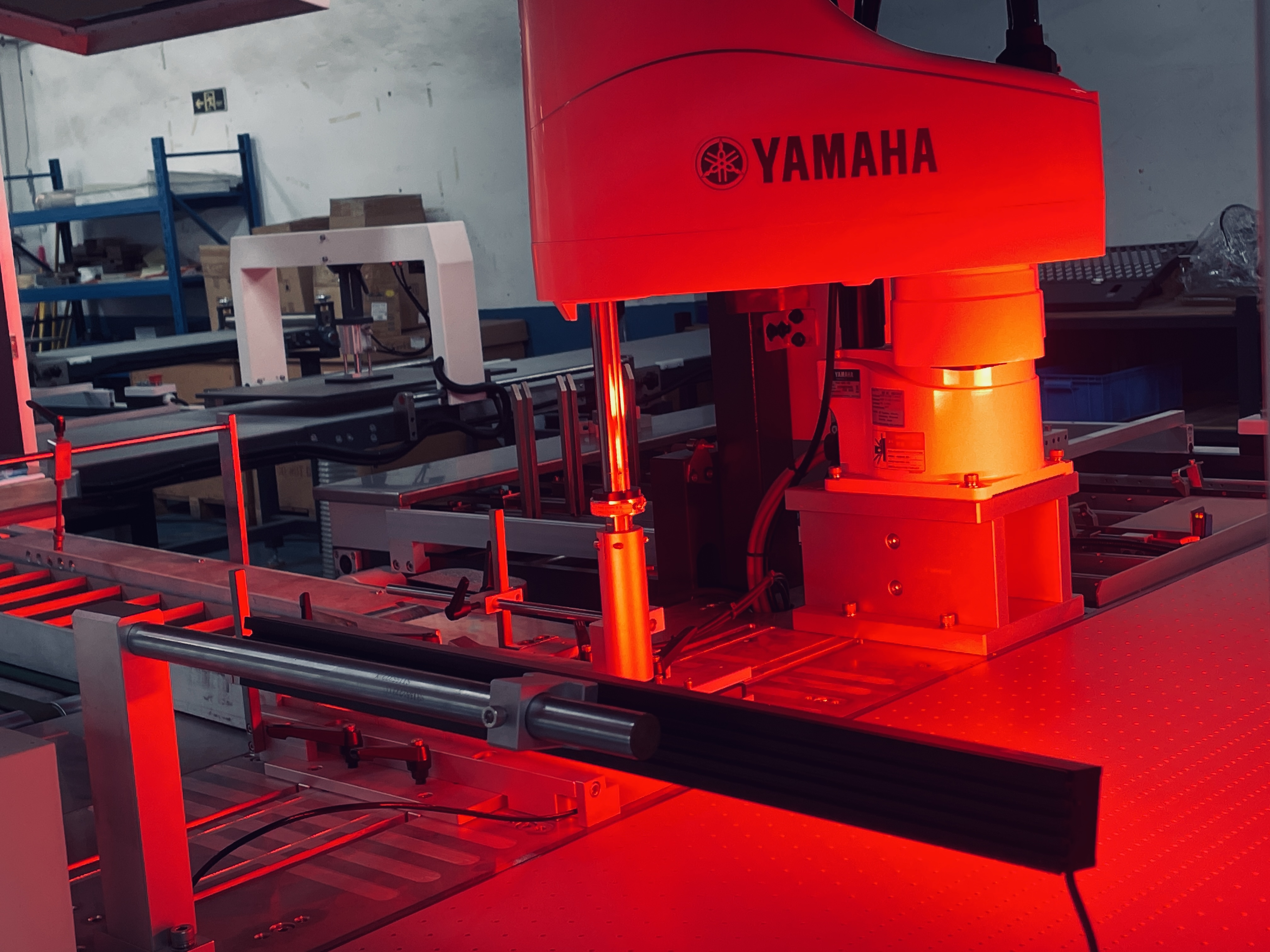

The Full Automatic Rigid Box Vision Positioning Machine is an intelligent machine that uses advanced technology to provide efficient and accurate results. It is equipped with a Programmable Logic Controller (PLC) that allows for precise control of the machine's movements and functions. In addition, it features a Mitsubishi servo motor & Yamaha robotic arm that further enhances its precision and efficiency. The machine is also equipped with high-performance and stable servo motors that allow it to operate smoothly and consistently.

Two high-pixel cameras transmit the captured clear pictures to the visual positioning system, and the two cameras do not need to move when changing the size of the box. The high-precision Yamaha robot precisely positions the box on the tissue paper, ensuring the stability of the high-speed operation of the machine.

This machine is suitable all kinds of hardcover making factories.

6. Anti-leaking gluing system.

Visual positioning system and machine grasp (positioning error less than 0.1mm)

Trouble shooting

Yamaha robotic arm

Automatic suction and feed cover paper and cardboard function

New cycle temperature control gluing system

High precision CAM paper feeding

HD camera positioning

Panasonic servo control system

The Full Automatic Rigid Box Vision Positioning Machine has received positive feedback from customers worldwide. Its advanced technology, high precision, and efficiency have made it a popular choice for packaging and printing companieSuitable for all kinds of automatic production lines

Visual positioning system and machine grasp (positioning error less than 0.1mm)

Trouble shooting

Yamaha robotic arm

Automatic suction and feed cover paper and cardboard function

New cycle temperature control gluing system

High precision CAM paper feeding

HD camera positioning

Panasonic servo control system

| Type | LS-450XL |

| Paper size (max) | L800*W600mm |

| Paper size (min) | L135*W100mm |

| Box size (max) | L600*W400*H120mm(optional) |

| size (min) | L80*W65*H15mm(opional) |

| Hard cover (max) | L750*W450mm |

| Hard cover (min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 450mm/100kg |

| Working speed | 15-40 sheet/min |

| Positioning accuracy | ±0.1mm |

| Motor power | 7.5kw/380v 3phase |

| Heating power | 8kw/380v 3phase |

| Air pressure | 10L/min 0.6MPa |

| Machine weight | 2400kg |

| Machine dimension | L5980*W3180*H2100mm |

This is a semi-automatic vision positioning machine. The maximum size of leather/book case that can be made is 750*450mm, and the minimum size is 150*100mm. 15-40 boxes can be made per minute. It can make book case, notebook case, novel leather case, case liner, paper lamination, etc. The machine runs fast. The suitcase conveyor belt can transport five suitcases at a time, which is the largest in the market. The conveyor belt has a suction function to prevent the suitcase paper from being scratched and effectively reduce the waste of customer materials.

The Full Automatic Rigid Box Vision Positioning Machine is an intelligent machine that uses advanced technology to provide efficient and accurate results. It is equipped with a Programmable Logic Controller (PLC) that allows for precise control of the machine's movements and functions. In addition, it features a Mitsubishi servo motor & Yamaha robotic arm that further enhances its precision and efficiency. The machine is also equipped with high-performance and stable servo motors that allow it to operate smoothly and consistently.

Two high-pixel cameras transmit the captured clear pictures to the visual positioning system, and the two cameras do not need to move when changing the size of the box. The high-precision Yamaha robot precisely positions the box on the tissue paper, ensuring the stability of the high-speed operation of the machine.

This machine is suitable all kinds of hardcover making factories.

6. Anti-leaking gluing system.

Visual positioning system and machine grasp (positioning error less than 0.1mm)

Trouble shooting

Yamaha robotic arm

Automatic suction and feed cover paper and cardboard function

New cycle temperature control gluing system

High precision CAM paper feeding

HD camera positioning

Panasonic servo control system

The Full Automatic Rigid Box Vision Positioning Machine has received positive feedback from customers worldwide. Its advanced technology, high precision, and efficiency have made it a popular choice for packaging and printing companieSuitable for all kinds of automatic production lines

Visual positioning system and machine grasp (positioning error less than 0.1mm)

Trouble shooting

Yamaha robotic arm

Automatic suction and feed cover paper and cardboard function

New cycle temperature control gluing system

High precision CAM paper feeding

HD camera positioning

Panasonic servo control system

| Type | LS-450XL |

| Paper size (max) | L800*W600mm |

| Paper size (min) | L135*W100mm |

| Box size (max) | L600*W400*H120mm(optional) |

| size (min) | L80*W65*H15mm(opional) |

| Hard cover (max) | L750*W450mm |

| Hard cover (min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 450mm/100kg |

| Working speed | 15-40 sheet/min |

| Positioning accuracy | ±0.1mm |

| Motor power | 7.5kw/380v 3phase |

| Heating power | 8kw/380v 3phase |

| Air pressure | 10L/min 0.6MPa |

| Machine weight | 2400kg |

| Machine dimension | L5980*W3180*H2100mm |