| Availability: | |

|---|---|

| Quantity: | |

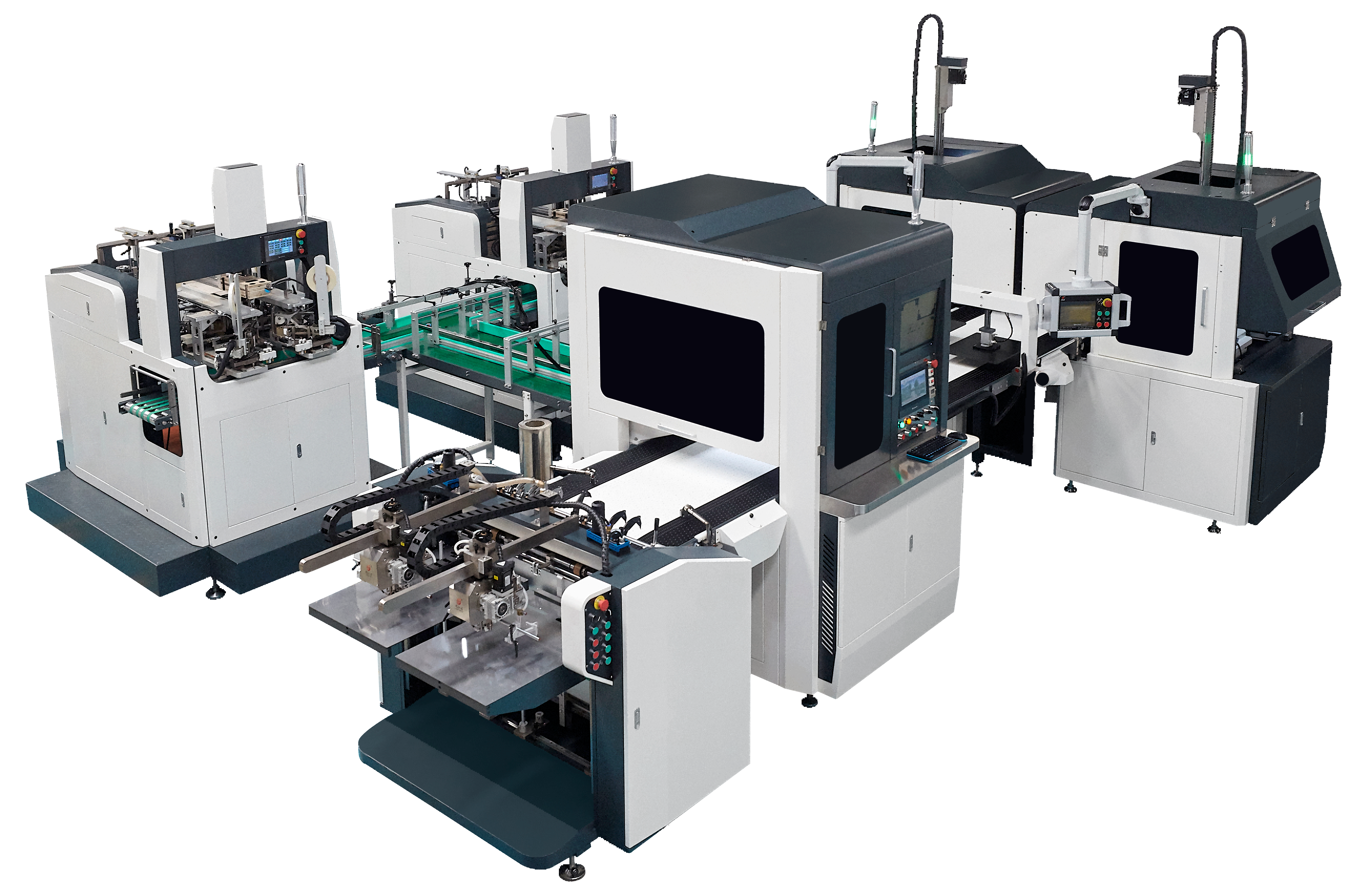

LS-900A

Longxingsheng

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

Efficiency and Precision Combined: Our Rigid Box Maker creates flawless, high-quality boxes with speed and accuracy, ensuring your packaging needs are met with excellence."

"Streamline Your Packaging Process: Our Box Making Machine revolutionizes the way you produce rigid boxes, optimizing productivity and minimizing manual labor. Experience seamless box assembly like never before."

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

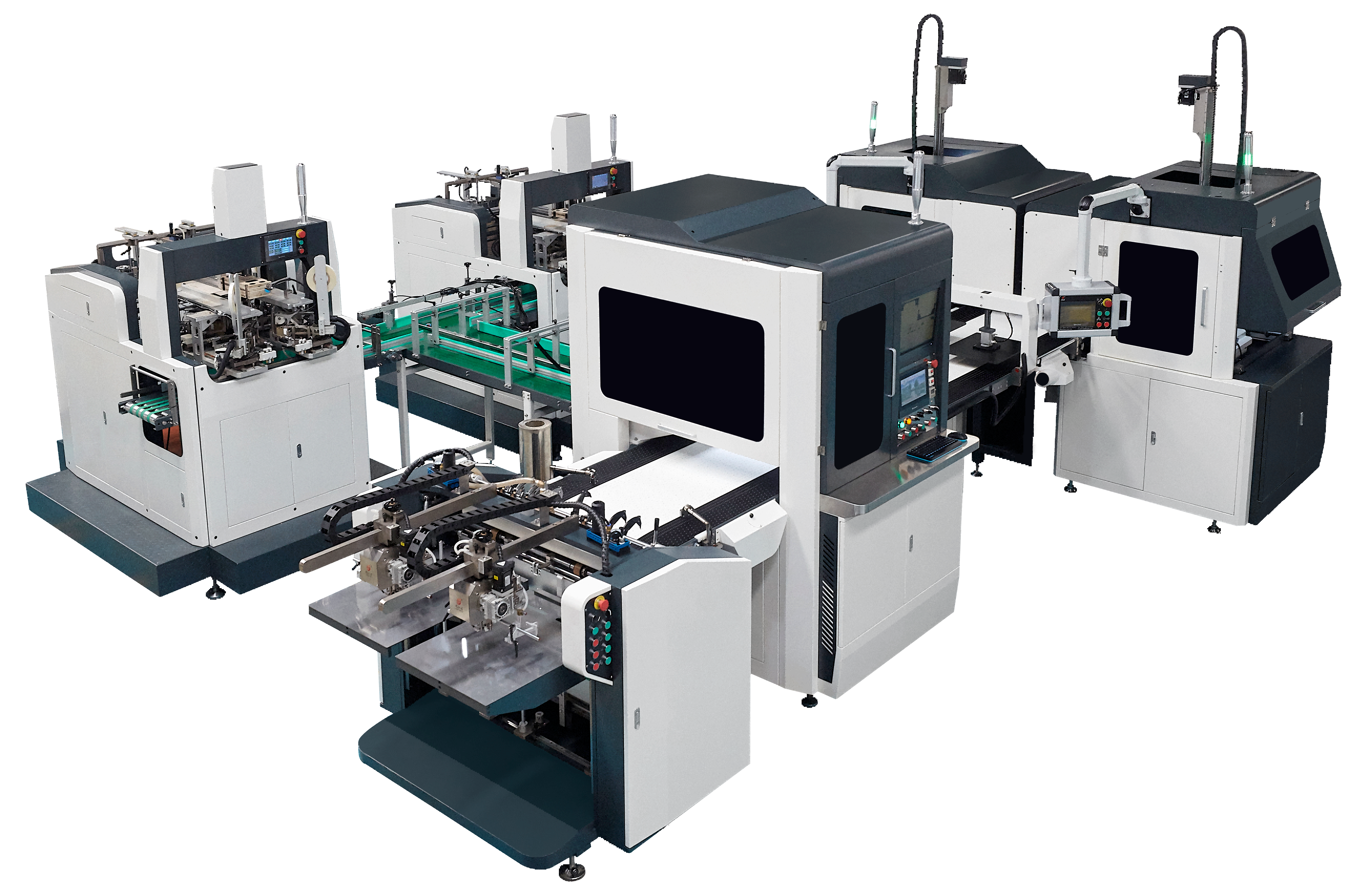

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

Efficiency and Precision Combined: Our Rigid Box Maker creates flawless, high-quality boxes with speed and accuracy, ensuring your packaging needs are met with excellence."

"Streamline Your Packaging Process: Our Box Making Machine revolutionizes the way you produce rigid boxes, optimizing productivity and minimizing manual labor. Experience seamless box assembly like never before."

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.