| Availability: | |

|---|---|

| Quantity: | |

LS-450XL

Longxingsheng

This is a semi-automatic visual positioning machine. The maximum case size is 750*450mm, and the minimum size is 150*100mm. It can make 15-40 pieces of cases per minute. It can make book cases, notebook cases, novel case cases, case linings, paper laminations, etc. The machine runs fast, and the leather case conveyor belt can transport five leather cases at a time, which is the most conveyed in the market, and the conveyor belt has a suction function to prevent the leather case paper from being scratched, effectively reducing the waste of customer materials.

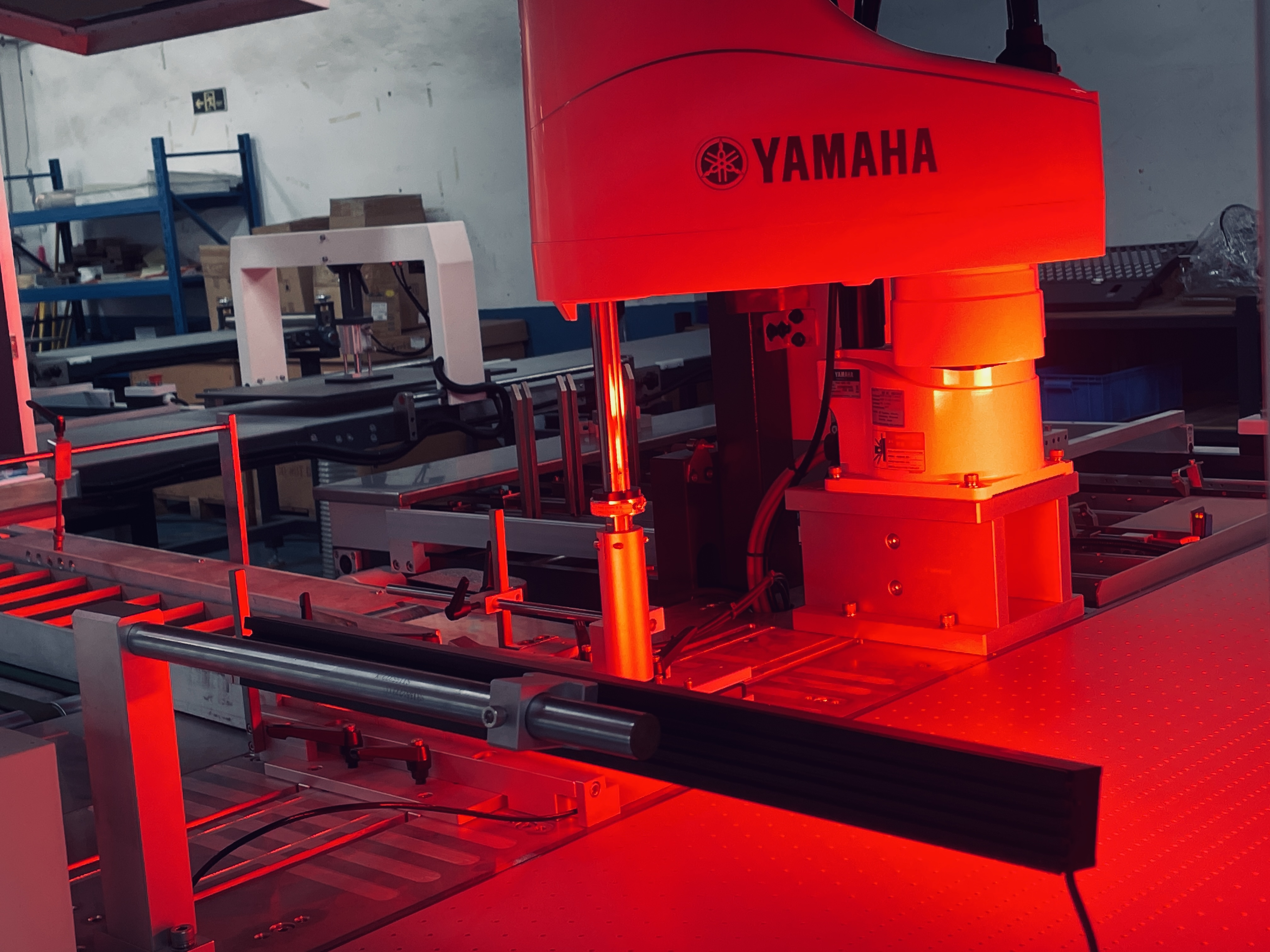

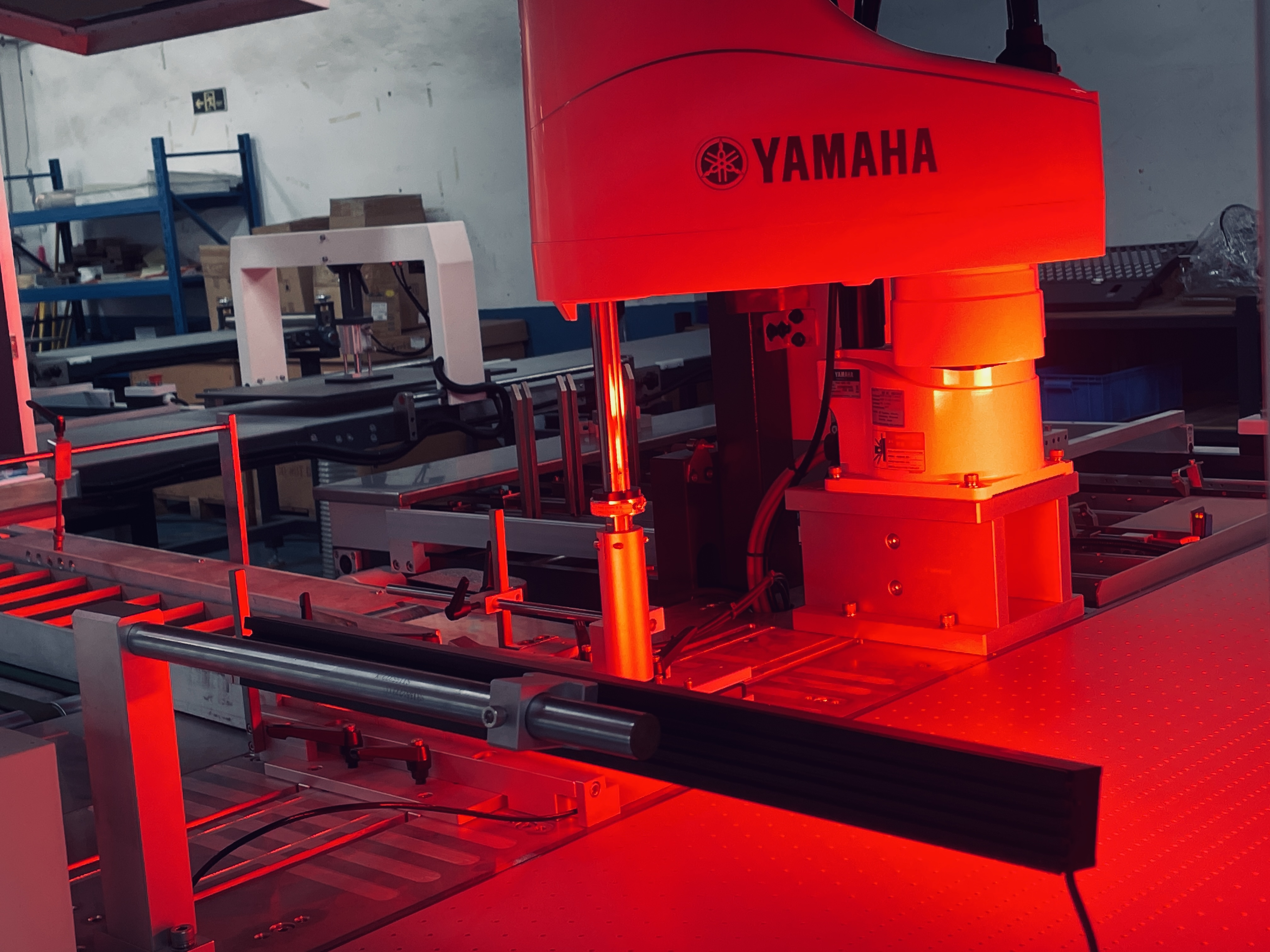

Two high-pixel cameras transmit the captured clear pictures to the visual positioning system, and the two cameras do not need to move when changing the size of the box. The high-precision Yamaha robot precisely positions the box on the tissue paper, ensuring the stability of the high-speed operation of the machine

1. Panasonic PLC

2. Anti-leaking gluing system

3. Servo motor feeding system

Visual positioning system and machine grasp (positioning error less than 0.1mm)

Quickly job setting

No need to move camera for size changing, quick job changing

Yamaha robotic arm

Automatic suction and feed cover paper and cardboard function

Panasonic servo control system

Storage(memory) function for sizes setting

Suitable for changeable orders

Such as 5,000 pcs for one order

| Type | LS-450XL |

| Paper size (max) | L800*W600mm |

| Paper size (min) | L135*W100mm |

| Box size (max) | L600*W400*H120mm(optional) |

| size (min) | L80*W65*H15mm(opional) |

| Hard cover (max) | L750*W450mm |

| Hard cover (min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 450mm/100kg |

| Working speed | 15-40 sheet/min |

| Positioning accuracy | ±0.1mm |

| Motor power | 7.5kw/380v 3phase |

| Heating power | 8kw/380v 3phase |

| Air pressure | 10L/min 0.6MPa |

| Machine weight | 2400kg |

| Machine dimension | L5980*W3180*H2100mm |

One of the main advantages of the fully automatic hard box vision positioning machine is its ability to provide precise positioning of hard boxes. This is achieved by using advanced vision technology, which enables the machine to detect and analyze the position of the box with high precision. This ensures that the boxes are correctly positioned and that subsequent production processes can proceed without any errors.

Another advantage of the fully automatic hard box vision positioning machine is its high efficiency. The machine is designed to run quickly, resulting in high output. This is especially important for companies that need to produce large quantities of products in a short period of time.

This is a semi-automatic visual positioning machine. The maximum case size is 750*450mm, and the minimum size is 150*100mm. It can make 15-40 pieces of cases per minute. It can make book cases, notebook cases, novel case cases, case linings, paper laminations, etc. The machine runs fast, and the leather case conveyor belt can transport five leather cases at a time, which is the most conveyed in the market, and the conveyor belt has a suction function to prevent the leather case paper from being scratched, effectively reducing the waste of customer materials.

Two high-pixel cameras transmit the captured clear pictures to the visual positioning system, and the two cameras do not need to move when changing the size of the box. The high-precision Yamaha robot precisely positions the box on the tissue paper, ensuring the stability of the high-speed operation of the machine

1. Panasonic PLC

2. Anti-leaking gluing system

3. Servo motor feeding system

Visual positioning system and machine grasp (positioning error less than 0.1mm)

Quickly job setting

No need to move camera for size changing, quick job changing

Yamaha robotic arm

Automatic suction and feed cover paper and cardboard function

Panasonic servo control system

Storage(memory) function for sizes setting

Suitable for changeable orders

Such as 5,000 pcs for one order

| Type | LS-450XL |

| Paper size (max) | L800*W600mm |

| Paper size (min) | L135*W100mm |

| Box size (max) | L600*W400*H120mm(optional) |

| size (min) | L80*W65*H15mm(opional) |

| Hard cover (max) | L750*W450mm |

| Hard cover (min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 450mm/100kg |

| Working speed | 15-40 sheet/min |

| Positioning accuracy | ±0.1mm |

| Motor power | 7.5kw/380v 3phase |

| Heating power | 8kw/380v 3phase |

| Air pressure | 10L/min 0.6MPa |

| Machine weight | 2400kg |

| Machine dimension | L5980*W3180*H2100mm |

One of the main advantages of the fully automatic hard box vision positioning machine is its ability to provide precise positioning of hard boxes. This is achieved by using advanced vision technology, which enables the machine to detect and analyze the position of the box with high precision. This ensures that the boxes are correctly positioned and that subsequent production processes can proceed without any errors.

Another advantage of the fully automatic hard box vision positioning machine is its high efficiency. The machine is designed to run quickly, resulting in high output. This is especially important for companies that need to produce large quantities of products in a short period of time.