| Availability: | |

|---|---|

| Quantity: | |

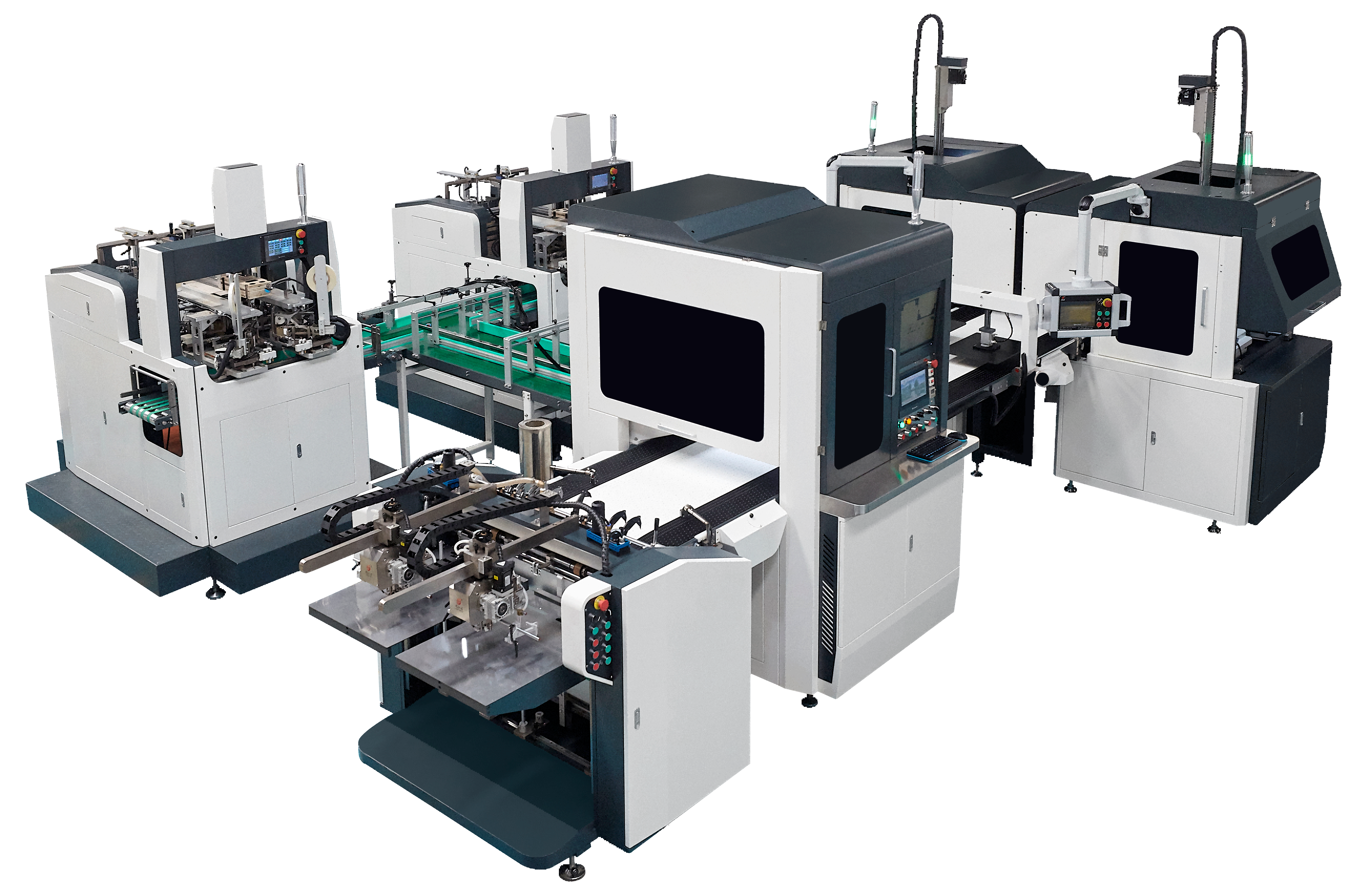

LS-900A

Longxingsheng

Welcome to LXS Tech's page featuring our Double Duty Hard Cover Rigid Box Positioning Machine. We are proud to present this innovative solution that enhances the efficiency and precision of manufacturing rigid boxes. Whether you are in the publishing industry, printing business, or packaging sector, our machine is designed to meet your specific needs.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

In order to ensure the normal operation of the top and bottom lid carton making machine and extend its service life, the following are some maintenance matters that need to be paid attention to:

1.Regular cleaning: Clean the internal and external parts of the carton making machine regularly, using a soft cloth or air pressure tool to remove dust and impurities. Pay special attention to cleaning critical components such as cutting tools and drivetrains.

2.Lubrication and maintenance: Lubricate key components regularly according to the box making machine's instruction manual. Use appropriate lubricants and ensure that the type and usage of lubricants meet the requirements of the carton making machine.

3.Check the electrical connections: Regularly check the electrical connections of the box making machine to ensure that the wire connectors are stable and reliable and are not loose or falling off. Make sure the power cord and plug are not damaged.

Whether you manufacture gift boxes, jewelry boxes, or premium product packaging, our Automatic Multi-functional Rigid Box Making Machine caters to your needs, adding unique value and appeal to your products.

Contact us now to learn more about the Automatic Multi-functional Rigid Box Making Machine and let us assist you in creating exquisite rigid box covers!

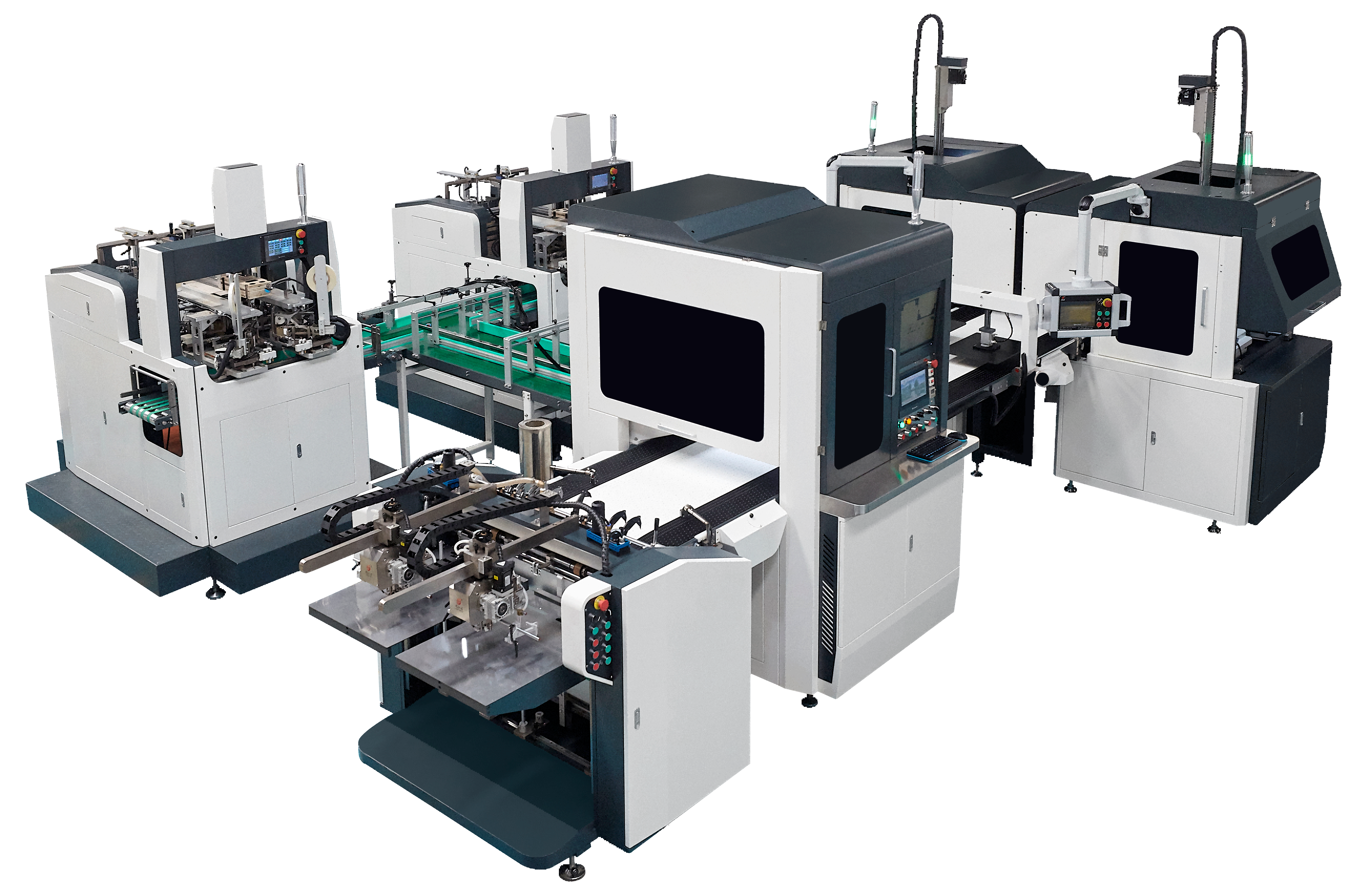

Welcome to LXS Tech's page featuring our Double Duty Hard Cover Rigid Box Positioning Machine. We are proud to present this innovative solution that enhances the efficiency and precision of manufacturing rigid boxes. Whether you are in the publishing industry, printing business, or packaging sector, our machine is designed to meet your specific needs.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

In order to ensure the normal operation of the top and bottom lid carton making machine and extend its service life, the following are some maintenance matters that need to be paid attention to:

1.Regular cleaning: Clean the internal and external parts of the carton making machine regularly, using a soft cloth or air pressure tool to remove dust and impurities. Pay special attention to cleaning critical components such as cutting tools and drivetrains.

2.Lubrication and maintenance: Lubricate key components regularly according to the box making machine's instruction manual. Use appropriate lubricants and ensure that the type and usage of lubricants meet the requirements of the carton making machine.

3.Check the electrical connections: Regularly check the electrical connections of the box making machine to ensure that the wire connectors are stable and reliable and are not loose or falling off. Make sure the power cord and plug are not damaged.

Whether you manufacture gift boxes, jewelry boxes, or premium product packaging, our Automatic Multi-functional Rigid Box Making Machine caters to your needs, adding unique value and appeal to your products.

Contact us now to learn more about the Automatic Multi-functional Rigid Box Making Machine and let us assist you in creating exquisite rigid box covers!