| Availability: | |

|---|---|

| Quantity: | |

LS-1200C

longxingsheng

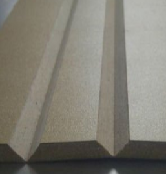

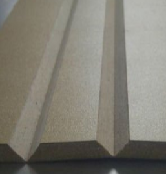

LS-1200C is a slitting machine that can automatically switch between horizontal and vertical slitting. It has functions such as angle adjustment, high-speed automatic feeding, automatic deviation correction, and automatic receiving. This machine can be used for cardboard and MDF boards.

Machine model | LS-1200C |

Grooving blade quantity | 4 |

Working speed | 35m/min(100-200pcs/min) |

Cardboard size | 140*120-600*600mm |

Cardboard thickness | 0.5-4mm |

Carton paper thickness | 500-800g/m2 |

Blade material | Tungsten steel |

Grooving speed | 100-130PCS |

Grooving Blade type | V grooving |

Min grooving gap (between two grooves) | 0 (2 lines blade design) |

Motor power | 4.5 kw/380v 3 phase |

Machine dimension | L2050*W1320*H1350mm |

Machine weight | 3520kg |

Precision is very important for grooving and this machine excels at it. Equipped with advanced sensors and cutting-edge technology to create precise slits with minimal errors. Not only does this improve the overall quality of the final product, it also reduces material waste, saving the manufacturer money.

In terms of safety, it is equipped with various safety features designed to protect workers and prevent accidents. Emergency stop buttons, guards, and automatic shut-off mechanisms are just a few examples of safety features built into the design. This ensures a safe working environment and peace of mind for operators and business owners.

LS-1200C is a slitting machine that can automatically switch between horizontal and vertical slitting. It has functions such as angle adjustment, high-speed automatic feeding, automatic deviation correction, and automatic receiving. This machine can be used for cardboard and MDF boards.

Machine model | LS-1200C |

Grooving blade quantity | 4 |

Working speed | 35m/min(100-200pcs/min) |

Cardboard size | 140*120-600*600mm |

Cardboard thickness | 0.5-4mm |

Carton paper thickness | 500-800g/m2 |

Blade material | Tungsten steel |

Grooving speed | 100-130PCS |

Grooving Blade type | V grooving |

Min grooving gap (between two grooves) | 0 (2 lines blade design) |

Motor power | 4.5 kw/380v 3 phase |

Machine dimension | L2050*W1320*H1350mm |

Machine weight | 3520kg |

Precision is very important for grooving and this machine excels at it. Equipped with advanced sensors and cutting-edge technology to create precise slits with minimal errors. Not only does this improve the overall quality of the final product, it also reduces material waste, saving the manufacturer money.

In terms of safety, it is equipped with various safety features designed to protect workers and prevent accidents. Emergency stop buttons, guards, and automatic shut-off mechanisms are just a few examples of safety features built into the design. This ensures a safe working environment and peace of mind for operators and business owners.