| Availability: | |

|---|---|

| Quantity: | |

LS-300B

Longxingsheng

This machine is equipped with advanced technology which enables it to produce rigid boxes of various sizes and shapes precisely and quickly. Its automated design increases productivity, making it ideal for businesses requiring high-volume production.

The automatic intelligent hard case box making machine has a user-friendly interface that is easy to learn and operate. Its main power source adopts the combination of Mitsubishi servo motor and Panasonic PLC to ensure stable operation.

1. Gluing part(paper gluing):The paper is separated into single sheet, the glue is evenly coated on the face paper

through the roller, and then the glued face paper is transported to the box positioning part by the conveyor belt.

2. Corner pasting part(cardboard corner pasting):Corner sticking machine: the feeding system sends the cardboard to the inside of the box making , and sticks the four corners of the cardboard to make it shape

3. Positioning part(box positioning):Grab the box by robotic arm, and position it on the glued paper by camera.

4.Forming part(box forming):Finish wrapping four sides and air pressing of box after positioning, and finally move

the finished boxes out of the production line from both sides of the machine.

1. Suitable for all kinds of automatic production line

2. Troubleshooting

3. Automatic suction, paper and cardboard feeding

4. High precision CAM paper feeding

5. Panasonic servo control system

6. Visual positioning system and robot grasp (positioning error less than 0.1mm)

7. Yamaha robotic arm

8. New cycle temperature control gluing system

9. Precise four-angle box holding robot

10. Precise sliding table folding, folding length can be adjusted

11. Built-in constant temperature system (optional)

12. HD camera positioning

Paper gluing&Cardboard corner pasting --Cardboard box positioning--box forming

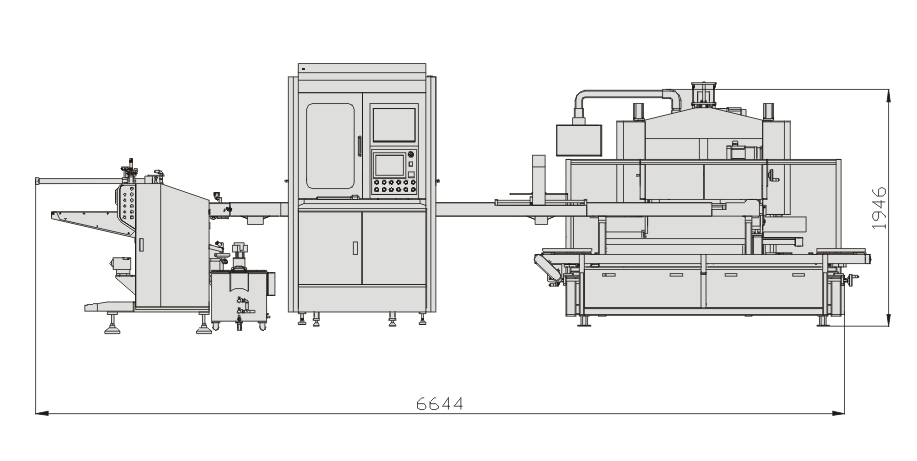

| Type | LS-300B |

| Paper size (max) | L800 * W600mm |

| Paper size (min) | L135 * W100mm |

| Cardboard size (max) | L760 * W560mm |

| Cardboard size (min) | L400 * W300 * H100mm |

| Box size (max) | L80 * W60 * H15mm |

| Cartoon paper thickness | 100-350g/㎡ |

| Cardboard thickness | 0.8-3mm |

| Edge folding size | 10-90mm |

| Tuin in depth | 15-80mm |

| Air pressure | 40L/min 0.8MPa |

| Working speed | 15-35 pcs/min |

| Motor power | 14kw/380v 3 phase |

| Heating power | 8kw |

| Weights | 5100kg |

| Dimension | L6600 * W3800 * H3000mm |

This machine is suitable for all kinds of rigid box making.It is good idear for box making manufacturer.

This machine is equipped with advanced technology which enables it to produce rigid boxes of various sizes and shapes precisely and quickly. Its automated design increases productivity, making it ideal for businesses requiring high-volume production.

The automatic intelligent hard case box making machine has a user-friendly interface that is easy to learn and operate. Its main power source adopts the combination of Mitsubishi servo motor and Panasonic PLC to ensure stable operation.

1. Gluing part(paper gluing):The paper is separated into single sheet, the glue is evenly coated on the face paper

through the roller, and then the glued face paper is transported to the box positioning part by the conveyor belt.

2. Corner pasting part(cardboard corner pasting):Corner sticking machine: the feeding system sends the cardboard to the inside of the box making , and sticks the four corners of the cardboard to make it shape

3. Positioning part(box positioning):Grab the box by robotic arm, and position it on the glued paper by camera.

4.Forming part(box forming):Finish wrapping four sides and air pressing of box after positioning, and finally move

the finished boxes out of the production line from both sides of the machine.

1. Suitable for all kinds of automatic production line

2. Troubleshooting

3. Automatic suction, paper and cardboard feeding

4. High precision CAM paper feeding

5. Panasonic servo control system

6. Visual positioning system and robot grasp (positioning error less than 0.1mm)

7. Yamaha robotic arm

8. New cycle temperature control gluing system

9. Precise four-angle box holding robot

10. Precise sliding table folding, folding length can be adjusted

11. Built-in constant temperature system (optional)

12. HD camera positioning

Paper gluing&Cardboard corner pasting --Cardboard box positioning--box forming

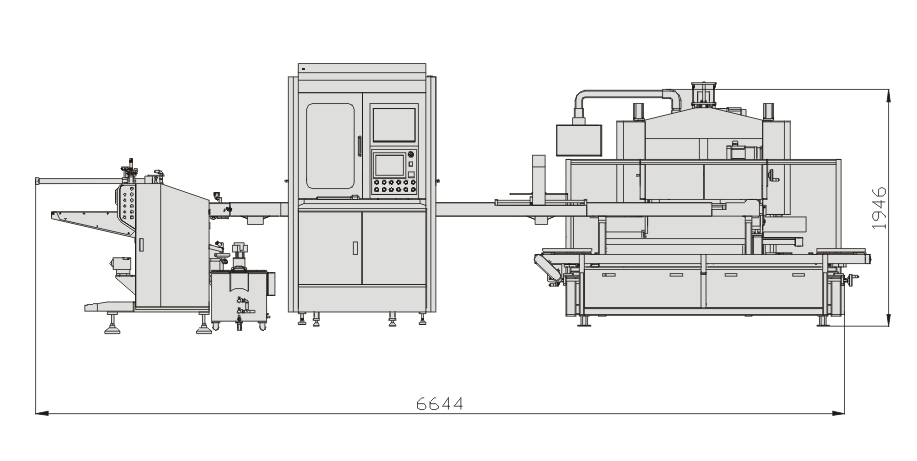

| Type | LS-300B |

| Paper size (max) | L800 * W600mm |

| Paper size (min) | L135 * W100mm |

| Cardboard size (max) | L760 * W560mm |

| Cardboard size (min) | L400 * W300 * H100mm |

| Box size (max) | L80 * W60 * H15mm |

| Cartoon paper thickness | 100-350g/㎡ |

| Cardboard thickness | 0.8-3mm |

| Edge folding size | 10-90mm |

| Tuin in depth | 15-80mm |

| Air pressure | 40L/min 0.8MPa |

| Working speed | 15-35 pcs/min |

| Motor power | 14kw/380v 3 phase |

| Heating power | 8kw |

| Weights | 5100kg |

| Dimension | L6600 * W3800 * H3000mm |

This machine is suitable for all kinds of rigid box making.It is good idear for box making manufacturer.