| Availability: | |

|---|---|

| Quantity: | |

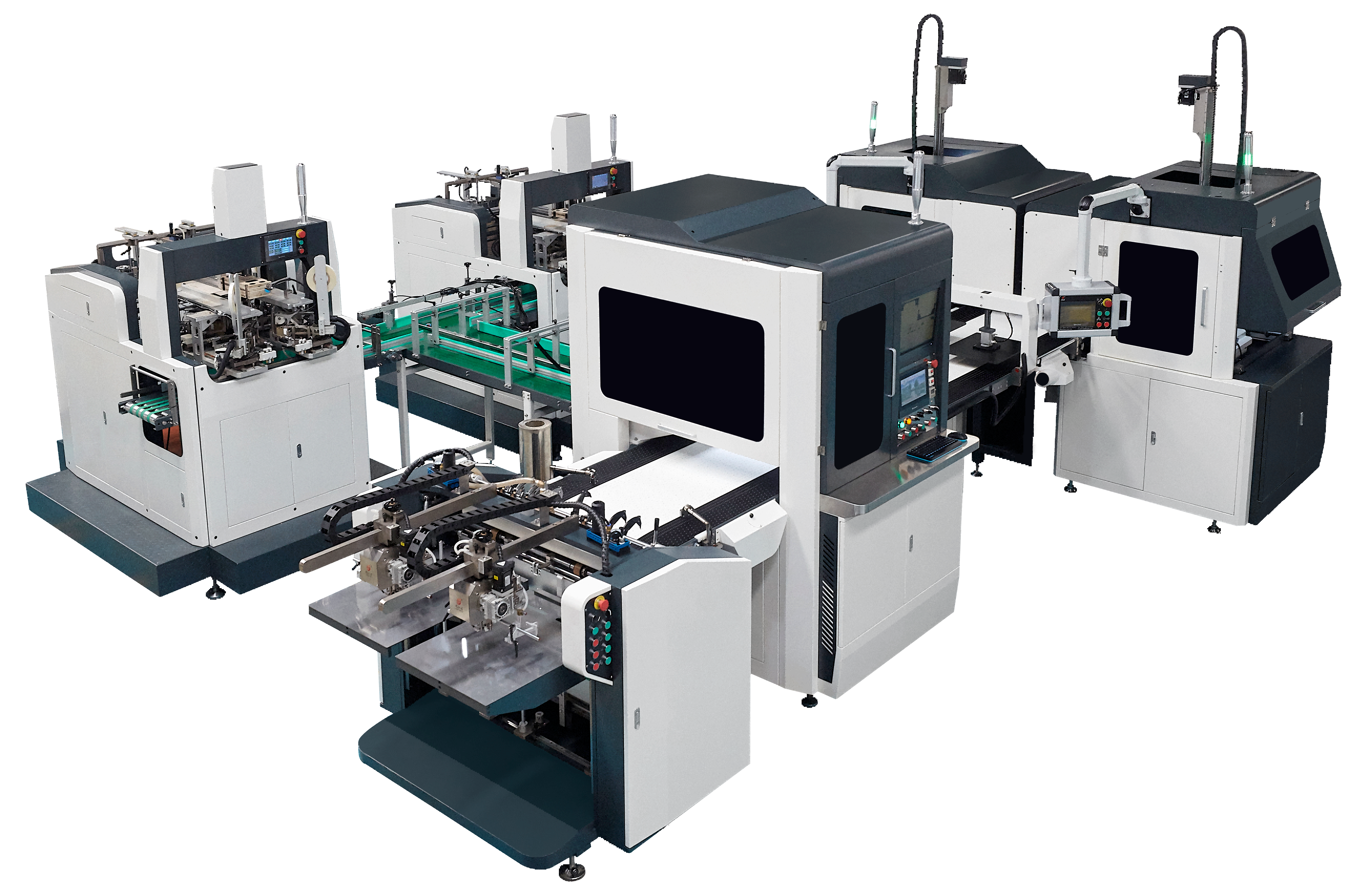

LS-900A

Longxingsheng

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

Efficient Paper Loading: The machine is equipped with a double feeding platform controlled separately, ensuring smooth and continuous paper loading.

Automated Feeding System: The feeder enables automatic cycle feeding, streamlining the production process.

Non-stop Belt Adjustment: A belt adjustment system is integrated into the machine, allowing for continuous and precise belt adjustment without interrupting production.

User-Friendly Gluing System: The integrated gluing guide groove simplifies the gluing process and facilitates easy cleaning.

Accurate Paper Feeding: The servo-driven cam feeder effectively prevents double paper feeding, ensuring precise and reliable paper feeding.

Advanced Computer Control: The machine boasts servo control with digital quick size adjustment, providing precise control and quick setup changes.

Versatile Box Positioning: The box positioning system accommodates a wide range of box sizes, offering flexibility in application. It also supports single-mode running.

Enhanced Box Bottom Adhesion: The machine features a second pressing mechanism that improves the sticking of the box bottom, ensuring secure and durable box construction.

Versatile Belt Options: The machine utilizes black and white belts, allowing for more color application and design possibilities.

High-Precision Robotic Arm: Equipped with a high-accuracy robotic arm with a tolerance of ± 0.1mm, the machine ensures precise and consistent box assembly.

Dual Camera System: The machine employs double cameras that operate independently, enabling high-speed and clear photo capturing for accurate positioning and alignment.

Increase your gift and luxury box production capabilities with our fully automatic box making machine, the Smart Rigid Box Forming Machine. Experience the benefits of production process optimization, superior quality, and customization options. Contact us today to learn more about this advanced solution and how it can enhance your packaging capabilities.

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

Efficient Paper Loading: The machine is equipped with a double feeding platform controlled separately, ensuring smooth and continuous paper loading.

Automated Feeding System: The feeder enables automatic cycle feeding, streamlining the production process.

Non-stop Belt Adjustment: A belt adjustment system is integrated into the machine, allowing for continuous and precise belt adjustment without interrupting production.

User-Friendly Gluing System: The integrated gluing guide groove simplifies the gluing process and facilitates easy cleaning.

Accurate Paper Feeding: The servo-driven cam feeder effectively prevents double paper feeding, ensuring precise and reliable paper feeding.

Advanced Computer Control: The machine boasts servo control with digital quick size adjustment, providing precise control and quick setup changes.

Versatile Box Positioning: The box positioning system accommodates a wide range of box sizes, offering flexibility in application. It also supports single-mode running.

Enhanced Box Bottom Adhesion: The machine features a second pressing mechanism that improves the sticking of the box bottom, ensuring secure and durable box construction.

Versatile Belt Options: The machine utilizes black and white belts, allowing for more color application and design possibilities.

High-Precision Robotic Arm: Equipped with a high-accuracy robotic arm with a tolerance of ± 0.1mm, the machine ensures precise and consistent box assembly.

Dual Camera System: The machine employs double cameras that operate independently, enabling high-speed and clear photo capturing for accurate positioning and alignment.

Increase your gift and luxury box production capabilities with our fully automatic box making machine, the Smart Rigid Box Forming Machine. Experience the benefits of production process optimization, superior quality, and customization options. Contact us today to learn more about this advanced solution and how it can enhance your packaging capabilities.